Accuracy is a crucial factor in ensuring that your auto labeling machine performs efficiently, especially in high-speed production environments. Misaligned or skewed labels can lead to costly product waste, customer dissatisfaction, and downtime. In this article, we will explore practical solutions to address the accuracy issues of your automatic labeling machine and help you achieve consistent, high-quality results every time.

1. Understand the Root Causes of Accuracy Problems

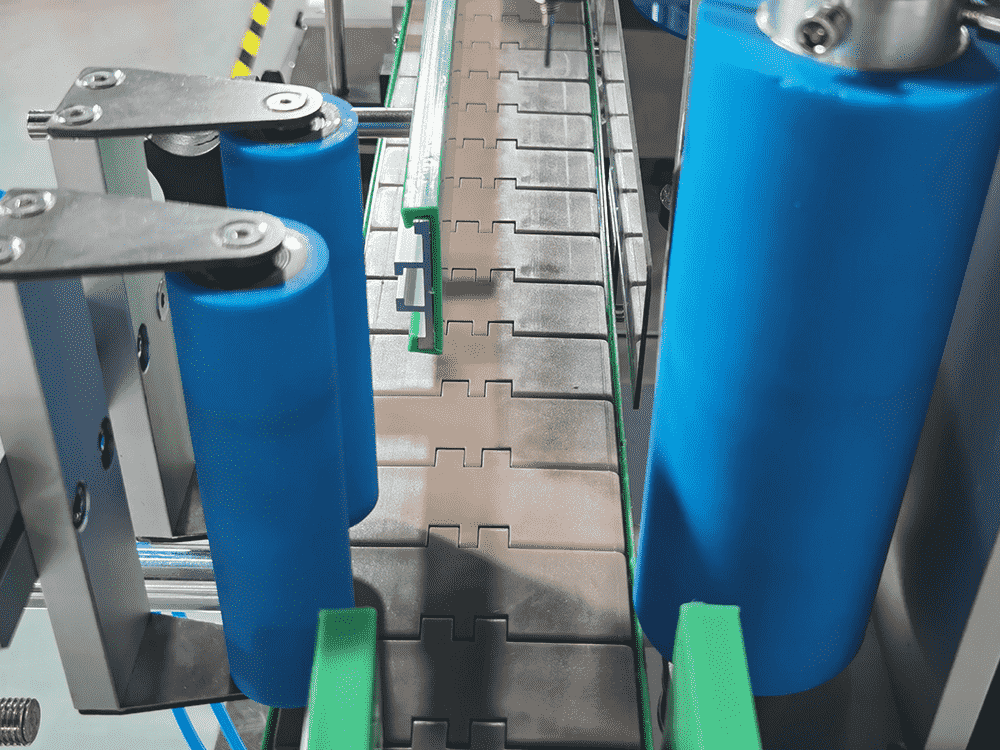

Before you can solve the accuracy issue, it’s essential to understand what might be causing it. Common problems include misaligned rollers, improper label feed, inaccurate sensor settings, or poor synchronization between the conveyor and labeling system. Identifying these root causes can guide you to the right solutions, whether it’s adjusting the machine’s setup or replacing worn-out components.

2. Proper Machine Setup and Calibration

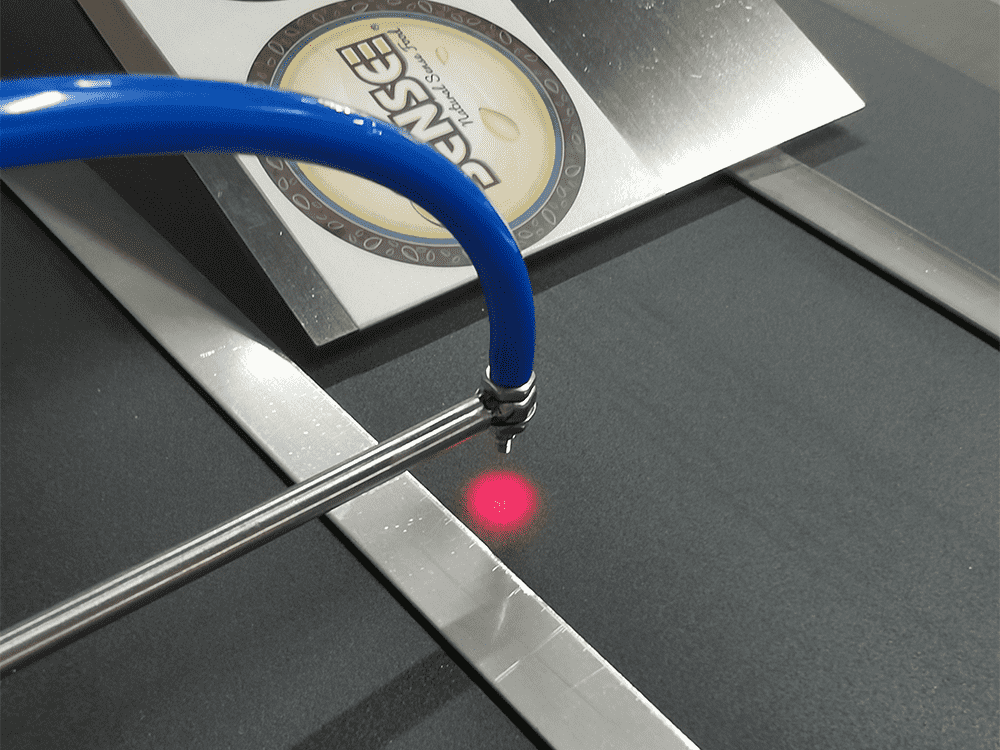

One of the most critical steps in solving accuracy issues is ensuring that the labeling machine is correctly set up and calibrated. Check the alignment of the label roll, the positioning of the product on the conveyor, and the applicator’s setup. Make sure the label size matches the machine’s settings and that the label feed mechanism is functioning correctly. Regular calibration of sensors and motors is also vital to ensure consistent label placement and avoid mislabeling.

4. Upgrade Labeling Components for Enhanced Precision

If your automatic labeling machine is still facing accuracy issues despite regular maintenance, it might be time to consider upgrading certain components. Installing high-precision sensors or a more accurate label application system can dramatically improve the accuracy of label placement. Additionally, using advanced software for real-time adjustments can help ensure the correct label position on every bottle or product.

Why Choose WINNEO Labeling Machines for Accuracy?

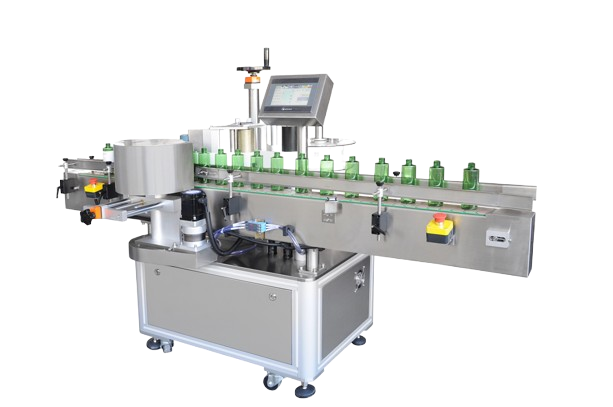

At Zhuonuo, our WINNEO brand offers state-of-the-art automatic labeling machines designed to enhance labeling accuracy and efficiency. WINNEO labeling machines are built with advanced technology to ensure precise label placement, even on challenging bottle shapes and sizes.

Our WINNEO labeling machine solutions are not only reliable but also easy to maintain and operate. With consistent performance, minimal downtime, and a user-friendly interface, our auto labeling machines are ideal for companies seeking precision and efficiency in their production processes.

In addition to high-quality products, WINNEO provides exceptional customer service. Our dedicated team offers tailored support, helping you troubleshoot issues, optimize machine performance, and ensure that your production line runs smoothly. We’re committed to helping you solve any accuracy problems and achieve the best results in your labeling process.

Trust WINNEO to enhance the accuracy and efficiency of your labeling machine. Contact us today to learn more about our products and services!

Work Time

Receive your information 24 hours a day

Beijing time: Monday to Friday 9:00-17:30