Technology Solutions

Ceramic Printing Solutions

The current ceramic printing industry faces multiple challenges in technology and process upgrades. As the market demand for refined decorative effects of ceramic products continues to increase, the printing process needs to meet the precise adaptation of both curved and flat surfaces. Especially in the printing of complex multi-color patterns, it is necessary to achieve high clarity of the pattern edge and high consistency of color, and break through the efficiency bottleneck of the traditional production model.

In the existing process, multi-color overprinting often relies on manual repeated positioning and multiple pick-and-place, which not only increases the complexity of operation, but also makes it easier to cause fluctuations in the overall printing quality due to slight deviations.

How to achieve automation and efficiency of multi-color printing processes under the premise of high precision and high stability has become the core proposition for promoting the industry's transformation to high-end and intelligent.

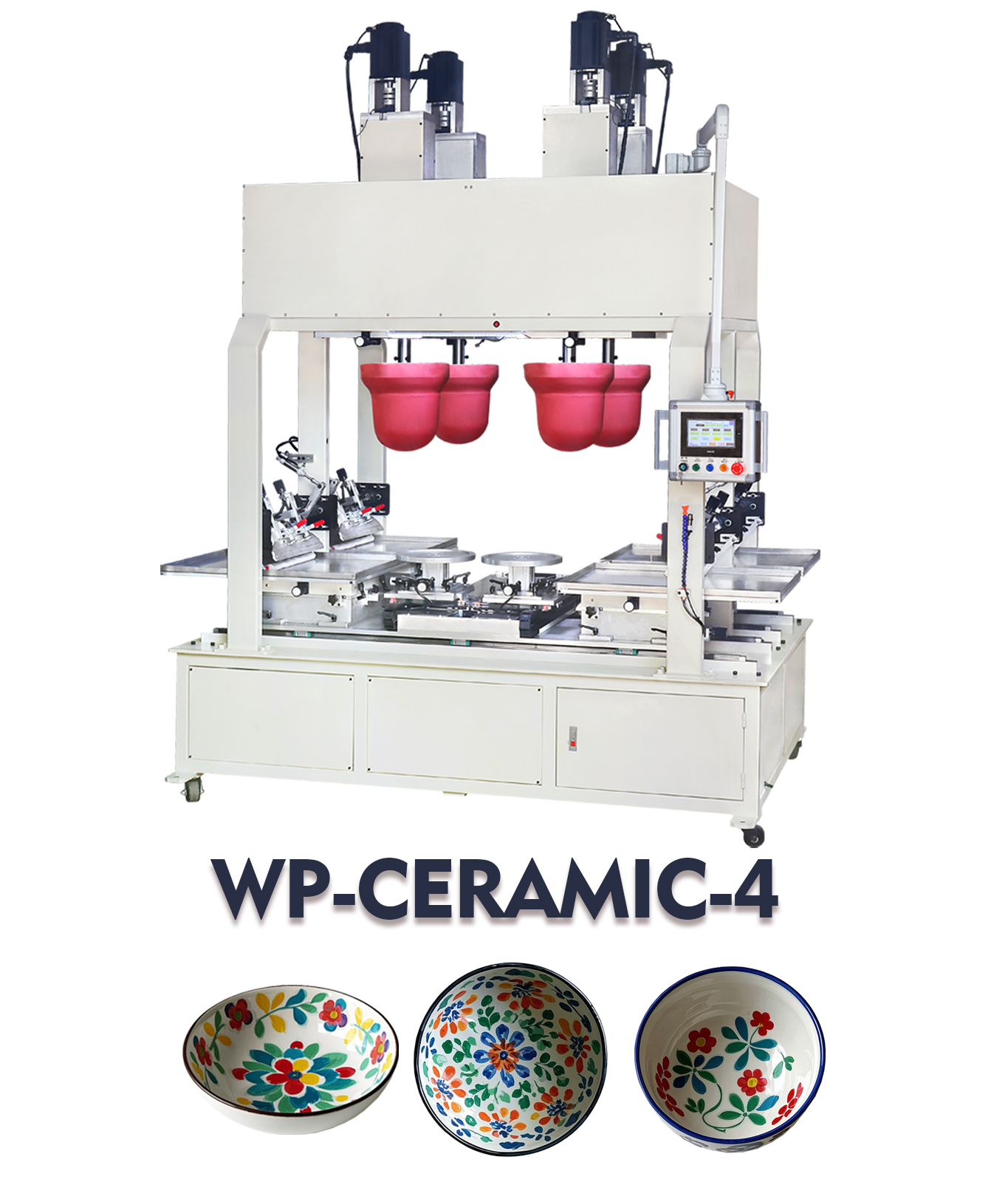

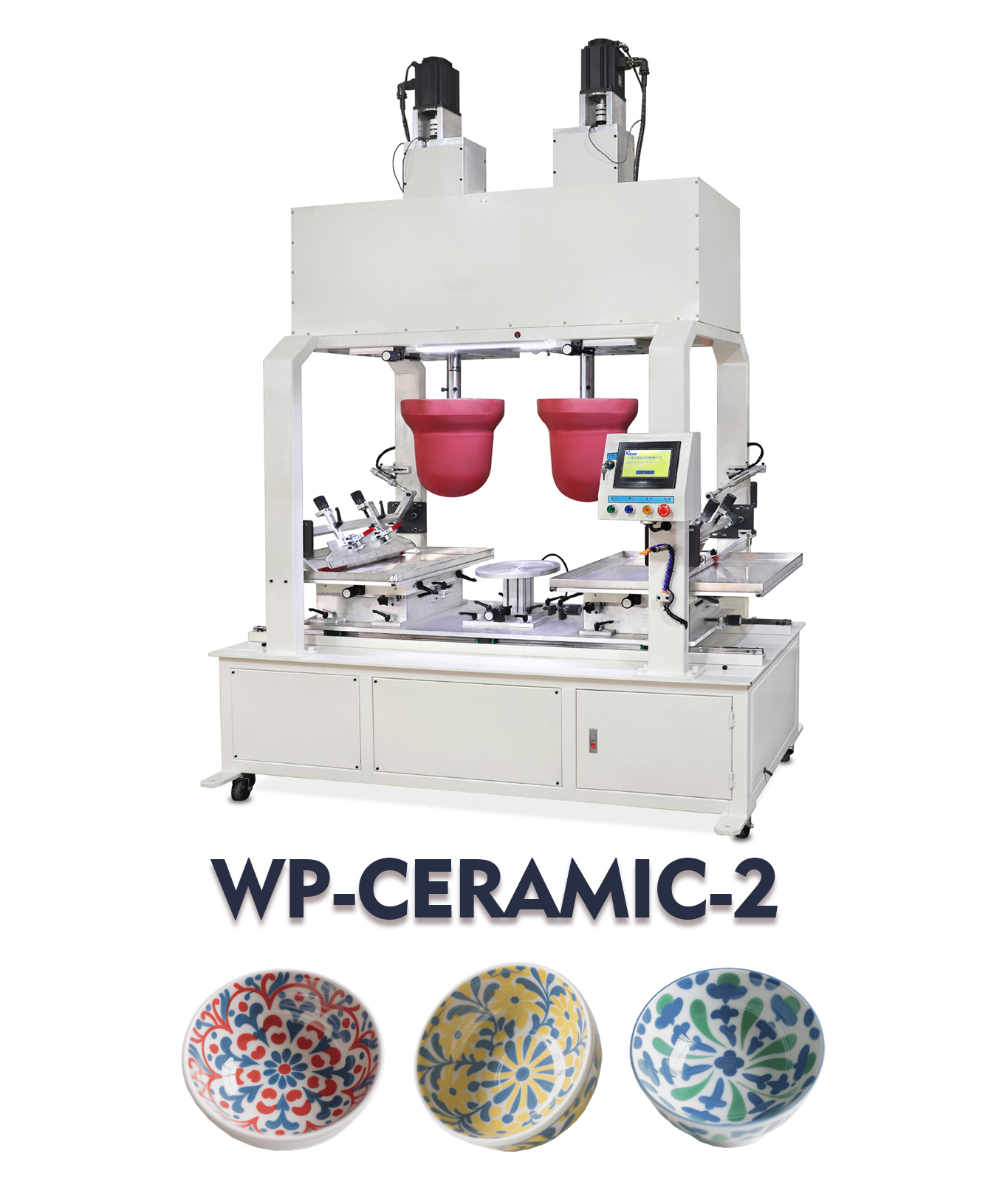

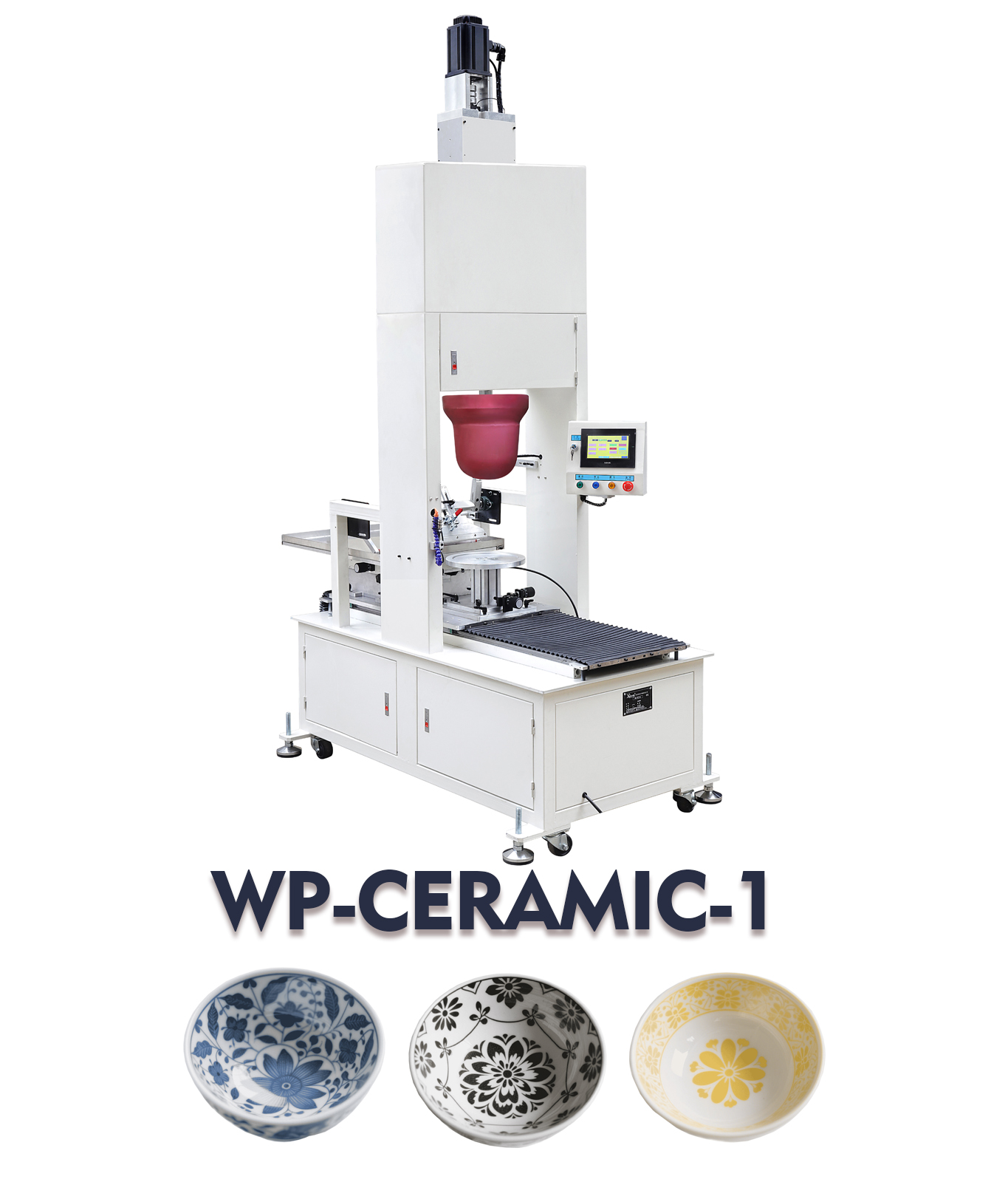

In response to the high precision and efficiency requirements of the ceramic printing industry, we provide a full range of single-color, two-color and four-color intelligent pad printing equipment to enable production upgrades with technological innovation.

Ceramic printing machine mainly used for tableware,dinnerware such as bowls, plates, dishes, ect. Material can be ceramic, porcelain, plastic, glass, wooden.

Our ceramic printing machines have the following features:

Precision transmission and intelligent control

The imported precision servo system and linear guide transmission combination ensures smooth operation of the equipment, low noise, and uniform and stable printing pressure. The PLC intelligent program centrally controls each execution action, which not only improves the reliability of the equipment, but also realizes one-button operation and quick maintenance, greatly reducing the complexity of manual operation and maintenance costs.

Efficient production and cost advantages

The equipment has the ability of high-speed continuous printing, significantly shortens the production cycle, and the efficiency of a single machine is more than 3 times higher than that of traditional processes. Ceramic printing adopts precise ink control technology, with a pigment utilization rate of up to 98%, and the comprehensive cost is reduced by about 50% compared with screen printing, and there is no need for multiple color baking, which completely solves the pain points of low efficiency and poor consistency of hand-painted processes.

Full-scene printing adaptability

The innovative printing head module can adapt to smooth glaze and concave and convex texture surfaces (adaptive depth up to 8mm), ensuring clear edges and accurate colors of various types of patterns. The printing area covers 50mm to 400mm, and is compatible with all kinds of ceramic products such as tea cups, soup plates, and large-size decorative plates, realizing flexible production with one machine for multiple uses.

Work Time

Receive your information 24 hours a day

Beijing time: Monday to Friday 9:00-17:30